Call Us For Carbide Tip

Band Saw Blade Maintenance Tools and Sharpeners Now

659.235.3565

Carbide Tip Band Saw Blade Maintenance Tools and Sharpeners

Discover essential tips for maintaining band saw blades in woodworking and metalworking. Learn about sharpening, storage, and selecting the right tools to ensure precision, safety, and longevity.

Call Us For Band Saw Blade Maintenance Tools and Sharpeners Now: 659.235.3565

Essential Tools for Precision and Longevity

Band saw blades are essential tools in woodworking and metalworking. They offer precision and efficiency in cutting various materials. However, to maintain their effectiveness, proper care and maintenance are crucial. This involves sharpening, storing, and understanding the different types of blades. Regular maintenance not only extends the life of the blades but also ensures safety and optimal performance. Choosing the right tools and techniques for sharpening and maintenance can significantly impact the quality of your work. Whether you’re a professional or a hobbyist, understanding the intricacies of band saw blade care can save time and money. This guide will delve into the essential aspects of band saw blade maintenance, from selecting the right sharpener to recognizing when a blade needs attention. By following these guidelines, you can ensure your band saw blades remain in top condition, providing clean and accurate cuts every time.

Call Us For Band Saw Blade Maintenance Tools and Sharpeners Now: 659.235.3565

Essential Maintenance Tools for Band Saw Blades

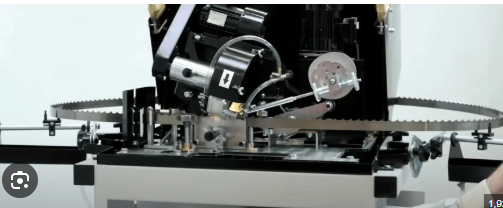

Proper maintenance of band saw blades requires the right tools. A blade tension gauge is essential. It ensures the blade is properly tensioned, preventing breakage and ensuring accurate cuts. Another crucial tool is a blade alignment tool. This helps maintain the correct blade position, reducing wear and tear. A blade cleaning brush is also important. It removes debris and resin buildup, which can affect cutting performance. For sharpening, a quality file or sharpening stone is necessary. These tools help maintain the blade’s sharpness, ensuring clean cuts. A lubricant is also vital. It reduces friction and heat, extending the blade’s life. Additionally, a blade tracking adjustment tool can help ensure the blade runs smoothly on the wheels. This prevents uneven wear and prolongs the blade’s lifespan. Lastly, a blade tension release tool is useful for releasing tension when the saw is not in use. This prevents unnecessary stress on the blade. By using these essential maintenance tools, you can keep your band saw blades in optimal condition, ensuring they perform efficiently and last longer.

Benefits of Regular Band Saw Blade Sharpening

Regular sharpening of band saw blades offers numerous benefits. First, it ensures clean and precise cuts. A sharp blade cuts through material smoothly, reducing the risk of splintering or rough edges. This is particularly important for projects requiring high precision. Additionally, sharpening extends the blade’s lifespan. A well-maintained blade is less likely to suffer from wear and tear, saving money on replacements. Regular sharpening also enhances safety. A dull blade requires more force to cut, increasing the risk of accidents. By keeping the blade sharp, you reduce the effort needed and improve control. Furthermore, sharpening improves efficiency. A sharp blade cuts faster and with less resistance, boosting productivity. It also reduces strain on the saw’s motor, preventing overheating and potential damage. Lastly, regular sharpening maintains the blade’s original tooth geometry. This ensures consistent performance and prevents uneven wear. By prioritizing regular sharpening, you can enjoy these benefits and ensure your band saw blades remain in top condition.

How to Choose the Right Band Saw Blade Sharpener

Selecting the right band saw blade sharpener is crucial for maintaining blade efficiency. Consider the type of blades you use. Different blades require different sharpening techniques. Look for a sharpener that accommodates the specific tooth configuration of your blades. Compatibility is key. Next, evaluate the sharpener’s ease of use. A user-friendly design can save time and reduce errors. Some sharpeners come with adjustable settings, allowing for precise control over the sharpening process. This feature is particularly useful for those who work with various blade types. Durability is another important factor. A well-built sharpener will withstand frequent use and provide consistent results. Check for quality materials and robust construction. Additionally, consider the sharpener’s speed and efficiency. Faster sharpeners can increase productivity, but ensure they don’t compromise on precision. Finally, assess the cost. While it’s tempting to opt for cheaper options, investing in a high-quality sharpener can save money in the long run by extending blade life and improving performance. By carefully considering these factors, you can choose a band saw blade sharpener that meets your needs and enhances your work.

Our Products

To operate a fabrication machine using carbide tip band saw blades, you primarily need the following products: a band saw machine, carbide-tipped band saw blades suitable for the materials you’re cutting, coolant to keep the blade cool during cutting, safety gear like eye protection and hearing protection, and potentially blade alignment tools to ensure proper blade placement on the wheels; depending on the specific application, you may also need specialized blades for different material types, blade tensioning tools, and a blade sharpening or replacement system.

Call Us For Band Saw Blade Maintenance Tools and Sharpeners Now: 659.235.3565

Coolant

Water-based, semi-synthetic coolant designed specifically for metal sawing applications, as it provides optimal lubrication and cooling while minimizing heat generation and extending blade life; depending on the material being cut, you may need to consider a full synthetic coolant option

Safety gear

Comprehensive safety gear designed for bandsaw operation, including safety glasses for eye protection, hearing protection to reduce noise exposure, dust masks to minimize inhalation of sawdust, and cut-resistant gloves for safe blade handling; avoid wearing gloves while operating the saw to prevent entanglement, and wear steel-toe boots along with fitted clothing to enhance overall safety and prevent accidents.

Maintenance

Blade cleaning tools: To remove debris from the blade and maintain cutting efficiency. Work holding devices: Clamps or vices to securely hold the material being cut on the band saw table. Blade sharpening equipment: If you plan to sharpen the carbide-tipped blades in-house. .