Call Us For Carbide Tip

Fabrication Bandsaw Blades Now

659.235.3565

Carbide Tip Band Saw Blades

For Metal Fabrication

Discover the game-changing benefits of carbide-tipped bandsaw blades for woodworking and metalworking. Learn about their durability, precision, selection criteria, maintenance tips, and more to elevate your craft. Call to talk one of our owners with 50+ years experience in the business.

Call Us For Fabrication Bandsaw Blades Now: 659.235.3565

You Get More For Your Money With Carbide Tip Band Saw Blades

Carbide-tipped bandsaw blades are a game-changer in the world of cutting tools. Known for their durability and precision, these blades are essential for anyone serious about woodworking or metalworking. They offer a significant upgrade over traditional steel blades, providing cleaner cuts and longer life. Whether you’re a professional craftsman or a hobbyist, understanding the benefits and proper use of carbide-tipped bandsaw blades can elevate your work to the next level. This post will delve into the advantages, selection criteria, maintenance tips, and more, ensuring you get the most out of your investment.

Call Us For Fabrication Bandsaw Blades Now: 659.235.3565

What are the advantages of carbide-tipped bandsaw blades?

Carbide-tipped bandsaw blades offer several key advantages. First, they are incredibly durable. The carbide tips are much harder than steel, allowing the blades to maintain their sharpness longer. This means fewer blade changes and less downtime.

Second, these blades provide cleaner cuts. The sharpness and durability of carbide tips result in smoother finishes, reducing the need for additional sanding or finishing work. This is particularly beneficial for precision tasks where accuracy is crucial.

Third, carbide-tipped blades are versatile. They can cut through a variety of materials, from hardwoods to metals, without losing their edge. This makes them a valuable tool for workshops that handle diverse projects.

Finally, they are cost-effective in the long run. While the initial investment may be higher, the extended lifespan and reduced need for replacements make carbide-tipped blades a more economical choice over time.

How to choose the right bandsaw blade for your material

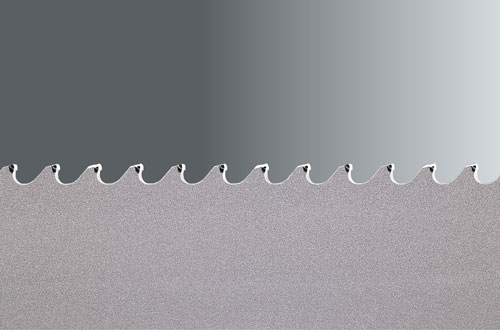

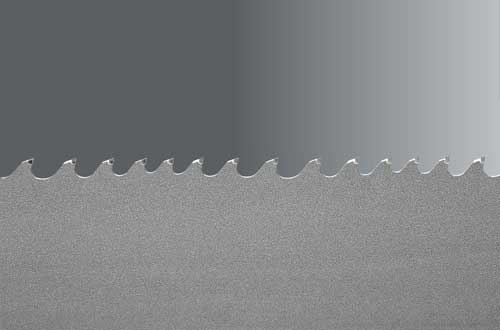

Choosing the right bandsaw blade for your material is crucial for achieving optimal results. Start by considering the type of material you will be cutting. Different materials require different blade specifications. For instance, cutting hardwoods demands a blade with fewer teeth per inch (TPI) to prevent clogging, while metals require a higher TPI for smoother cuts.

Next, think about the thickness of the material. Thicker materials need a wider blade to maintain stability and prevent deflection. Conversely, thinner materials can be cut with narrower blades for more intricate work.

Blade width is another important factor. Wider blades are more stable and suitable for straight cuts, while narrower blades are better for curves and intricate designs.

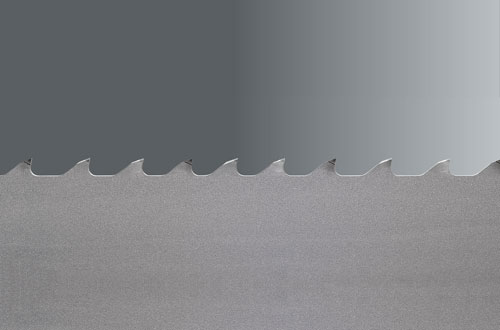

Lastly, consider the tooth configuration. Blades with alternate top bevel (ATB) teeth are excellent for cross-cutting wood, while those with a triple-chip grind (TCG) are ideal for cutting metals.